Privacy policy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Privacy policy

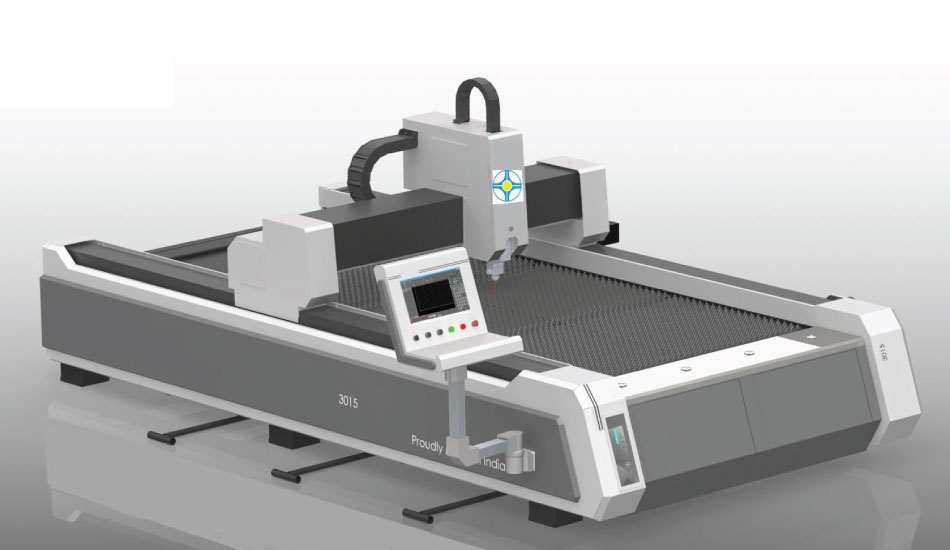

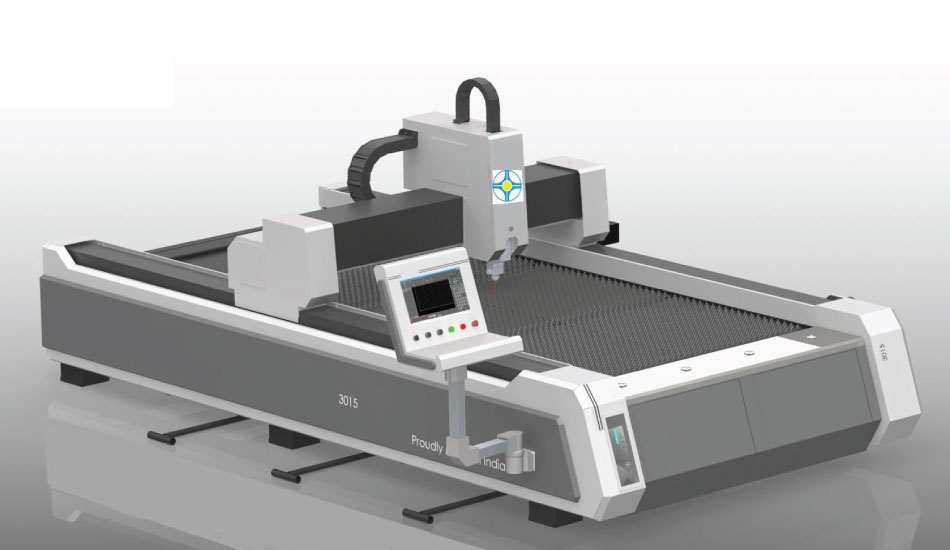

At SIDDHAPURA, we understand your diverse needs in sheet metal machinery, tools, automated software, and more, offering a comprehensive one-stop solution

Privacy policy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.